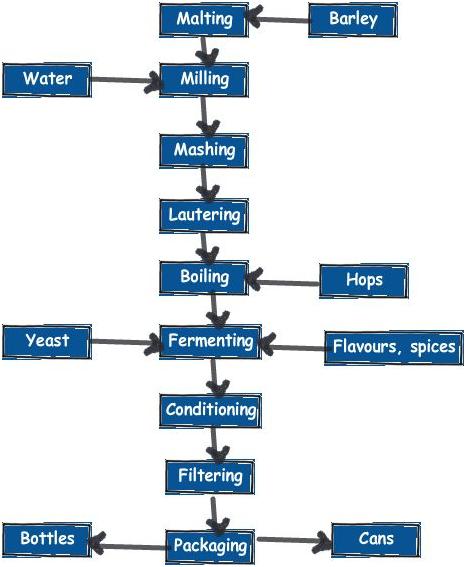

Beer Brewing Process

Brewing of alcoholic beer requires a series of steps, to make a good beer. The

brewing process goes through the phases of Malting, Milling, Mashing, Lautering,

Boiling, Fermenting, Conditioning, Filtering, and Packaging.

a. Malting: Here there is the conversion from carbohydrates to dextrin and

maltose. The grain generally used as the raw material is barley, which as a cereal

can be preserved for a long time after harvesting. The malted barley gives Beer

its characteristic taste and color.

b. Milling: The malt is mixed with water to complete the conversion of starches

in the grain to sugar.

c. Mashing: This process converts the starches released during the malting

stage, into sugars which is then used in the fermentation process.

d. Lautering: The liquid which is extracted from mashing has sugar, is then

separated from the grains. It is then called as wort.

e. Boiling and Hopping: The wort is properly boiled to sterilize and to ensure

that there is no infection. Hops are then added during this stage of boiling to add

flavor and aroma to achieve the sweetness of the malt.

f. Fermenting: In the fermenting process, yeast is added to produce the Beer.

The yeast helps to break down the sugars extracted from the malt to generate

alcohol and CO2.

g. Conditioning: The fermented Beer is not desireably stable which lacks

required level of carbonation, taste and aroma and it contains suspended

particles. Conditioning activity helps to reduce the levels of these undesirable

compounds and enables to produce more desireable product.

h. Filtering: Filtering is the process which produces the clear, bright and stable

Beer by removing excess yeast and unwanted solids, like hops or grain particles

from the fermented and conditioned Beer.

i. Packaging: The final finished beer is now ready to be bottled, kegged and

canned.

HOME

ABOUT US

BREWING PROCESS

GOLDEN BEER

DARK BEER

MANGO BEER

KEGS BEER

CHIANG MAI BEER

GRIZZLY BEER

AFFILIATES

CONTACT US

Call : 866 219 4736

Naturally brewed for spicy couisine